The forthcoming workshop at the Impulse Summit for Hydrogen and Fuel Cells in Vancouver on hydrogen and fuel cells in port applications provides an opportunity to follow up on last month’s blog post by taking a deeper dive into port operations and the high-intensity equipment required at them. We identify limitations of battery technology by examining the duty cycles of port equipment, and how fuel cells can be an enabler for vehicle electrification.

For fleet operators, there are compelling value drivers for electrified port equipment – whether fuel cell or battery-driven – that include:

- Increasing energy efficiency

- Reducing equipment maintenance costs associated with mechanical and hydraulic drivetrains

- Eliminating burning of diesel by port equipment internal combustion engines

- Eliminating diesel fuel handling

- Lowering noise in urban population centers

- Lowering the cost of regulatory compliance

- Eliminating greenhouse gas, nitrogen and sulfur oxides, and particulate matter engine emissions

Port equipment includes a wide range of vehicles and machinery: top loaders, reach stackers, forklifts, rubber tire gantries, yard trucks, and more. Today, diesel internal combustion engines power virtually all the equipment in service.

There are two (and only two) options for equipment electrification: batteries and fuel cells. So, which to use when?

In North America, port operations typically have three duty cycle types (Yard, Dock and Rail) and operate in three shifts. Let’s look at the energy usage profile of each of these applications.

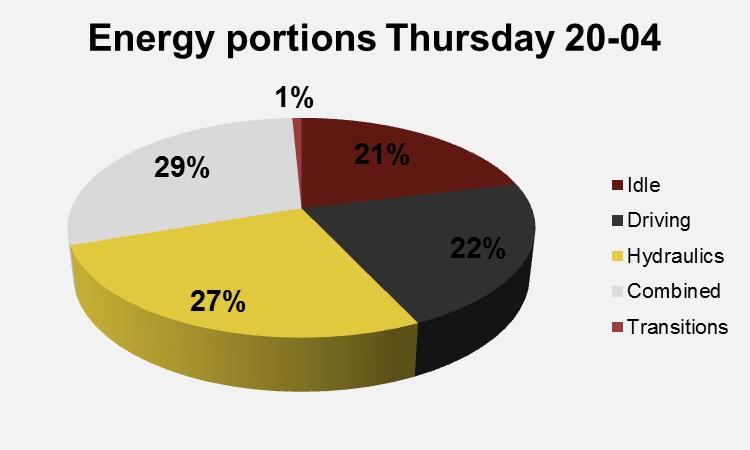

Yard and Dock duty cycles have three breaks per eight-hour shift: 15 minutes, 90 minutes, and 15 minutes. Up to 21 percent fuel energy is used during engine idling in a 24-hour period, according to representative load monitoring completed at the Port of Los Angeles and elsewhere by Hyster-Yale Group. Driving, hydraulics, and combined operation account for 78 percent of energy use.

Yard and Dock Energy Usage

Yard and Dock Energy Usage

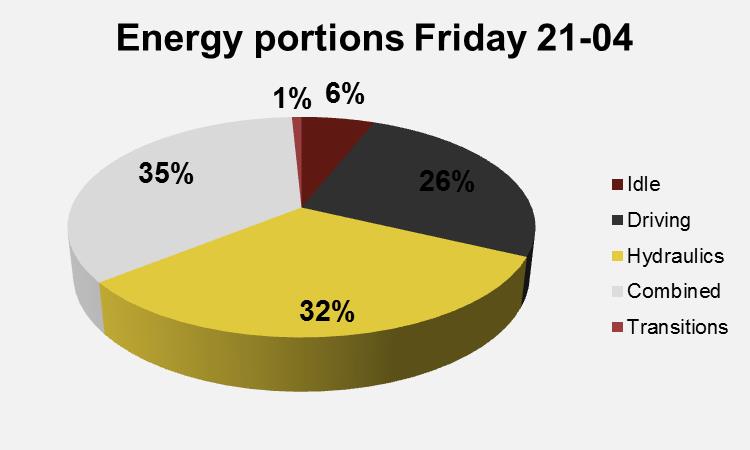

Rail duty cycles are a more intensive operation than either Yard or Dock and operate for up to seven hours with no break. Only three-to-six percent fuel energy is used during engine idling. Up to 93 percent of energy is consumed for driving, hydraulics, and combined operations.

Rail Energy Usage

Rail Energy Usage

Battery sizing for typical Rail usage would require approximately 800 kWh capacity. A lithium ion battery this size is very large – about the size of small African elephant.

Young African Elephant (L), Li-Ion Battery (R)

Unfortunately, the space available for a battery on board a top-loading container handler used for this purpose is only 1.1 m3. A lithium ion battery of this size is rated at 400 kWh, half the energy storage required.

This example illustrates a heavy-duty application when a fuel cell-battery hybrid solution, fueled by hydrogen, makes sense. If the battery is downsized to 200 kWh, it allows room for 20 kg of hydrogen stored on-board at 350 bar, along with a 45 kW fuel cell range extender. The combined energy from the batteries and hydrogen equals approximately 530 kWh (after accounting for 50 percent fuel cell efficiency). This isn’t enough to make it through the entire shift, but since the hydrogen tanks can be refueled quickly (e.g., from a mobile refueler towed to the equipment, as is done now with diesel), it is a feasible solution. The power system weight is also less than a battery-only solution, so less energy is used while the vehicle is traveling.

Hydrogen Fast-Fueling

Hydrogen Fast-Fueling

Higher-pressure hydrogen storage allows the top loader to carry enough hydrogen to make it through the entire rail cycle without refueling. While 350 bar hydrogen storage is the current standard for most industrial vehicles such as forklifts, 700 bar storage is the norm for passenger cars. The logistical benefit of increased energy capacity may justify the investment in the higher-pressure hydrogen storage system. Liquid hydrogen storage options, which have a higher energy density than 700 bar gaseous hydrogen, could also be developed using commercially available technology.

Although fuel cells are an option for virtually any electric power requirement, they excel at higher intensity applications that are continuous throughout the day. High-intensity operations require both higher power output and greater energy storage. Batteries are a challenging option because, at the scale of large industrial machinery, the weight and size of batteries required generally overwhelms the vehicle capacity.

Hyster-Yale Group, the parent company of Nuvera, recently announced it is developing a fuel cell reach stacker for the Port of Valencia as part of the European Horizon 2020 programme and the H2Ports project. The port will be the first in Europe to incorporate hydrogen energy in its operations. H2Ports follows a similar development in the Port of LA and the electrification of a Hyster® laden container handler that incorporates a Nuvera® fuel cell engine. These projects reinforce the case study presented here ─ and advance the adoption of hydrogen and fuel cells at ports already underway.

To learn more about our work for the ports, visit our blog.

Follow us on Twitter, connect with us on LinkedIn and like us on Facebook to stay up-to-date on the exciting things happening at Nuvera.