Hydrogen fuel cell forklifts are not just an economical fit for mega-warehouses with fleets of 100 trucks or more. Nuvera’s on-site hydrogen generator is helping fuel cell power make sense for modest-sized fleets as well. For example, a Nuvera hydrogen-supplied fleet was able to switch to fuel cells with only seven reach trucks and 10 pallet jacks that consume about 25 kg of hydrogen in 24 hours. The daily cost savings achieved with a hydrogen-powered fleet easily justified the investment.

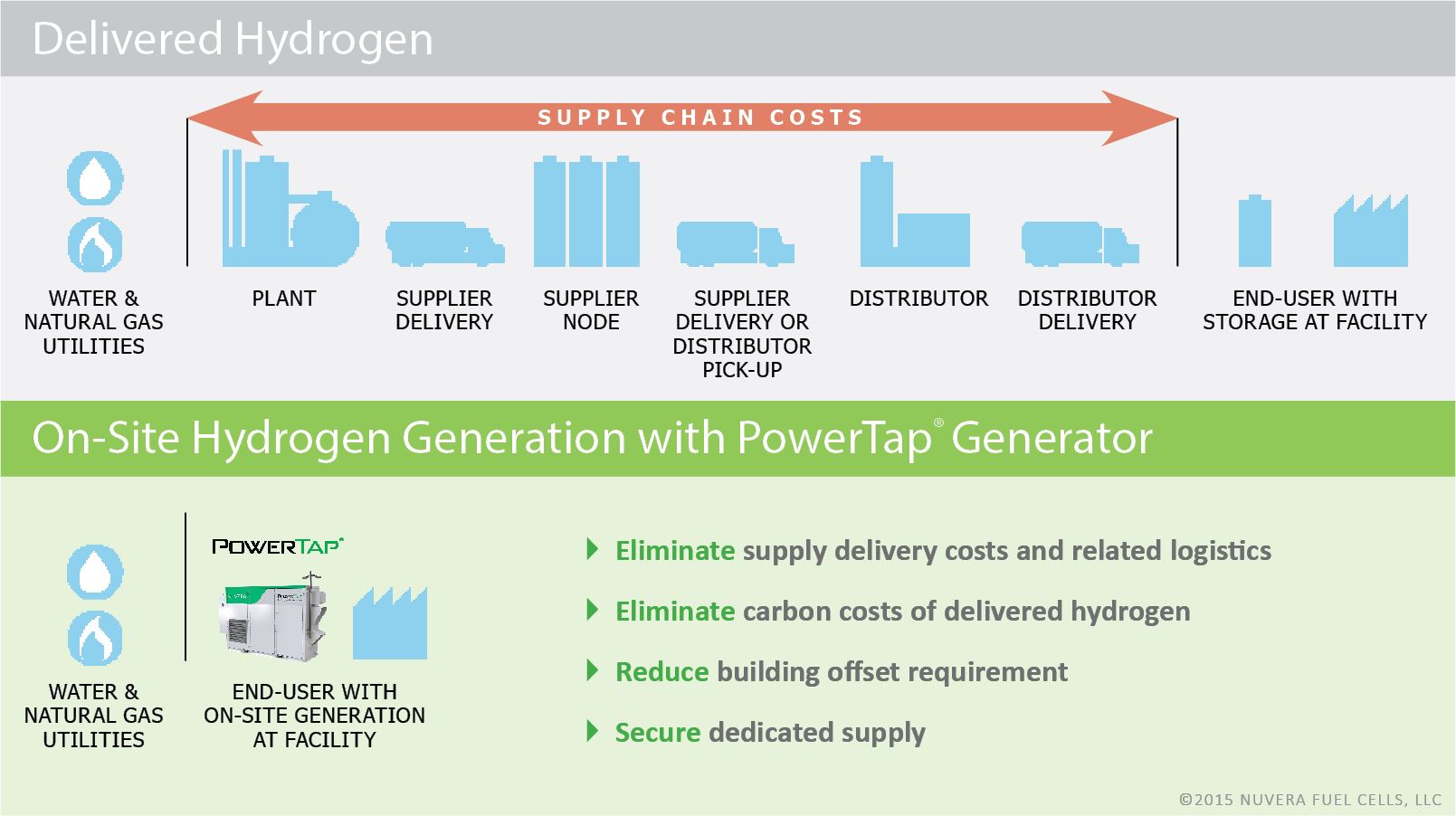

What Nuvera offers, in this and other examples, is an alternative helping eliminate costs associated with conventional hydrogen supply (ongoing carbon, delivery and logistical costs of trucking hydrogen). Delivered hydrogen requires permitting associated with larger storage space requirements than on-site production. Nuvera is proving its low-cost solution for the 25-150 kg/day range, taking steam methane reforming – by far the most efficient process of hydrogen production — and scaling it for modular installation at the point of use.

On-site hydrogen generation is enabling a more efficient and clean hydrogen supply chain.

Efficient hydrogen production is no longer just the province of large-scale chemical plants. Today, even modest-sized distribution centers, warehouses and manufacturing plants can produce hydrogen directly at the point of use – fueling lift trucks as quickly and easily as fueling a car at a filling station. That’s how Nuvera is helping expand the sweet spot for a growing fuel cell market.

Learn why fuel cell and hydrogen offerings are making big in-roads the fuel cell lift truck market in the latest analysis from Modern Materials Handling. (http://www.mmh.com/article/elevating_the_fuel_cell_lift_truck_market)