Meet Nuvera’s director of marketing and corporate development, Gus Block. Gus is engaged in global marketing, new business development, government affairs, and strategic planning initiatives that help drive positive outcomes for Nuvera, its industry partners, and society at large. As you’ll discover, he is also a lifelong thing-maker.

In 2022 Gus was named to the Environment+Energy Leader 100, an annual list that recognizes the environment and energy “doers” who craft new solutions, programs, platforms, best practices and products. Gus is among the Nuvera founding members that are still with the company 22 years later, and has had a variety of roles including systems engineering, product development, project management, and industry advocacy.

We asked Gus about his current focus at Nuvera, his views on fuel cell industry trends, and the activities he enjoys pursuing (besides being a card-carrying hydrogen revolutionary).

Tell us about your work at Nuvera.

One of the best parts of my job is identifying how Nuvera’s products and services can deliver meaningful outcomes for government and industry partners and creating opportunities for positive policy and business results. The common themes in most conversations I have with customers and collaborators are about fuel cells are reducing carbon and toxic air emissions, improving productivity, and minimizing total cost of ownership for the next generation of commercial vehicles and equipment.

Nuvera makes high-efficiency hydrogen fuel cell power systems that can power electrified versions of today’s diesel equipment: trucks, buses, industrial vehicles, and marine vessels, to name a few. Electrifying these platforms has many benefits – not least zero emissions, less maintenance and high performance. Battery-only power systems aren’t always the right answer because of weight, size, charging time, environmental conditions, and other limitations.

Fuel cell electric vehicles (FCEVs) are a good alternative when fast fueling, light system weight, or high power is required. With the ability to provide greater energy storage capacity than battery electric vehicles, FCEVs are well-suited to long-distance routes, requirements for extended daily operation, and applications requiring auxiliary power, like agriculture, construction and mining equipment, and transport refrigeration. I help match our technology, product, and application development activities with opportunities where Nuvera fuel cell products and services can help maximize our customers’ long-term success.

A great way to engage with current and potential partners is by being active in government and industry groups. I’ve been a delegate to the governor’s Zero Emissions Vehicle Commission in Massachusetts since it began in 2014, chair the communications and marketing committee of the Fuel Cell and Hydrogen Energy Association, and serve on the board of the California Hydrogen Business Council.

What trends do you expect to see in the market in the next few years? What challenges will the industry face and what technologies or organizational changes will overcome them?

There’s been a huge shift in focus towards hydrogen solutions across many industries over the last 20 years, most notably in on- and off-road transportation. The primary trend is being driven by the demand for high-performance, zero-emissions vehicles and equipment, national and international targets for reducing or eliminating carbon emissions, and regulations that are curtailing the use of diesel-powered equipment to improve air quality and mitigate climate disruption.

Because fuel cells are the only solution that work for some of the transport sectors that are the most difficult to decarbonize, and because hydrogen can be produced without reliance on fossil fuels, it is inevitable that these technologies will be a major part of the clean transportation future.

“Clean transportation” is a pretty broad category. What industries or markets are of particular interest now?

One in particular: Ports. There are many ways that green hydrogen and fuel cells will help decarbonize the world’s shipping ports, which are concentrated sources of emissions from diesel equipment. These include carbon dioxide, the most common human-made greenhouse gas, and chemical toxins like NOx, SOx, and particulate matter, which are serious health hazards for workers, truckers, and residents of communities in the vicinity of ports. Given how significant the air quality impact from port equipment is, not to mention the climate effect of CO2 emissions from equipment powered by fossil fuels, reducing diesel emissions can make a huge difference, both locally and globally.

To reduce port emissions while maintaining the productivity of terminal operations, Nuvera partnered with Hyster-Yale Group, our parent company and a leading port equipment provider, to develop a fuel cell electric container handler in a project funded by the California Air Resources Board. This type of vehicle is used to handle fully loaded shipping containers delivered to or leaving the port by ship, truck, or rail locomotive. There can be hundreds of container handlers at a major port, typically used for at least two shifts a day. A single machine can emit 128,000 kg of carbon dioxide per year.

The Hyster® hydrogen fuel cell toploader developed under this project is now operational at Fenix Marine Services, a terminal operator at the Port of Los Angeles, and is undergoing trials in daily service. This is the first step in the development of a commercially available version and is expected to be followed by other hydrogen fuel cell solutions, including yard trucks, reach stackers, and empty container handlers. With the proper infrastructure established ― ideally providing hydrogen produced from entirely renewable sources, such as solar or wind-powered electrolysis of water ― hydrogen can replace many diesel-powered operations at a port.

I’m also very excited about POWERS: Port Opportunities with Energy, Resilience and Sustainability, a new initiative of the American Association of Port Authorities, which Nuvera is a member of. This program is advocating for energy security, port equipment electrification, and supply chain resilience in the face of extreme weather events.

A huge area of opportunity for hydrogen lies in the development of offshore wind resources. Some of the power generated by these projects will likely be used to store electricity as hydrogen, which will be transmitted to shore via pipeline and used in fuel cells for both transportation and stationary applications, like container handling equipment and microgrids to provide supplemental power when the primary grid is constrained. As future importers and exporters of hydrogen – not to mention as direct consumers of hydrogen for terminal operations – ports will expand their role as major energy gateways incorporating renewable fuels at a scale that is orders of magnitude higher than today.

Tell us about your favorite pursuits – are there any that have impacted your work?

Wooden boatbuilding has been both vocation and avocation for me for the past forty years. It combines many elements of things I am passionate about: the integrity of craftsmanship (a boat not well made will likely sink, so the stakes are pretty high!), the beauty of natural materials and of forms that take shape in response to function, adventure and interaction with the sea – our most wild and unexplored place, yet one that covers three quarters of our planet’s surface. I agree with Buckminster Fuller that boatbuilding is the grandaddy of mechanical engineering – the field I entered after a decade of working as a boatwright, and which led to my career in hydrogen out of a concern with the societal and environmental consequences of energy systems.

Still a practitioner at the low end of the technology spectrum, I continue building wooden boats like the ones below, mostly for my own use. A recent project is a wooden sea kayak that allows me to explore the Gulf of Maine and the Canadian Maritimes.

I like the idea of making the things better by making better things. For me, wooden boats are a response to that personal impulse, and hydrogen fuel cells a response an urgent global imperative.

Any parting thoughts?

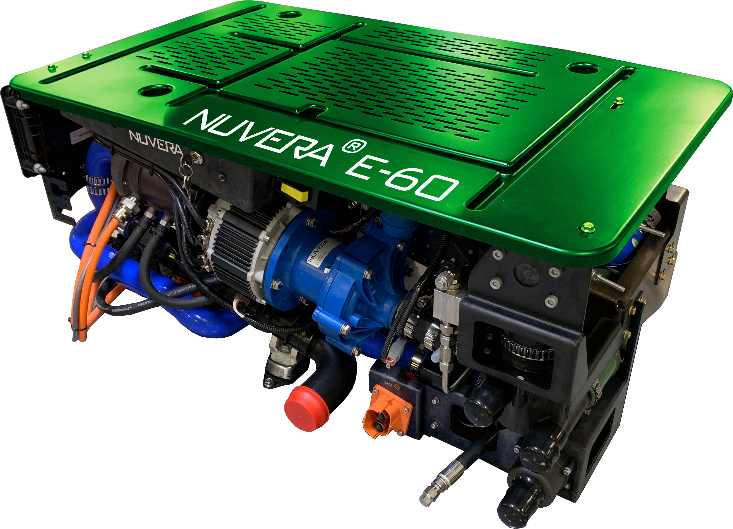

It’s been extremely rewarding to work alongside so many exceptional colleagues at Nuvera. Decades of product and technology development have culminated in the potentially disruptive innovation we call fuel cell engines, which put eight generations of Nuvera fuel cell technology advancement to work in very demanding on- and off-road motive applications in a way that’s easy to integrate into zero-emission powertrains.

The hydrogen tide is rising, lifting all providers in this industry that is already providing solutions to some of the most daunting challenges of our time. I am proud to be part of Nuvera – which started small and remains a mighty leader of the hydrogen revolution.