Matt Weig is the platform leader for the Nuvera E-Series Fuel Cell Engine flagship product line. Matt brings more than two decades of manufacturing engineering, product development, and business experience to the company, which he joined in 2017. We asked Matt to describe how his team engages in the process of continuous improvement for Nuvera’s fuel cell power systems for medium- and heavy-duty transportation and industrial applications.

Matt Weig is the platform leader for the Nuvera E-Series Fuel Cell Engine flagship product line. Matt brings more than two decades of manufacturing engineering, product development, and business experience to the company, which he joined in 2017. We asked Matt to describe how his team engages in the process of continuous improvement for Nuvera’s fuel cell power systems for medium- and heavy-duty transportation and industrial applications.

One of the questions I am asked most frequently as leader for Nuvera’s engine product platform is “what comes next?” The world’s economies are at just the beginning of the hydrogen revolution, and as the market for fuel cells evolves there is a steady demand for a wider range of power offerings, more features, and new applications. While it’s exciting to see the amazing number of ways fuel cells will transform transportation and other hard to decarbonize energy-consuming sectors like mining, construction, and agriculture, it’s also important to lay the groundwork with robust products that provide reliable and efficient performance, day in and day out, with cost of ownership on par with (or better than!) conventional diesel solutions.

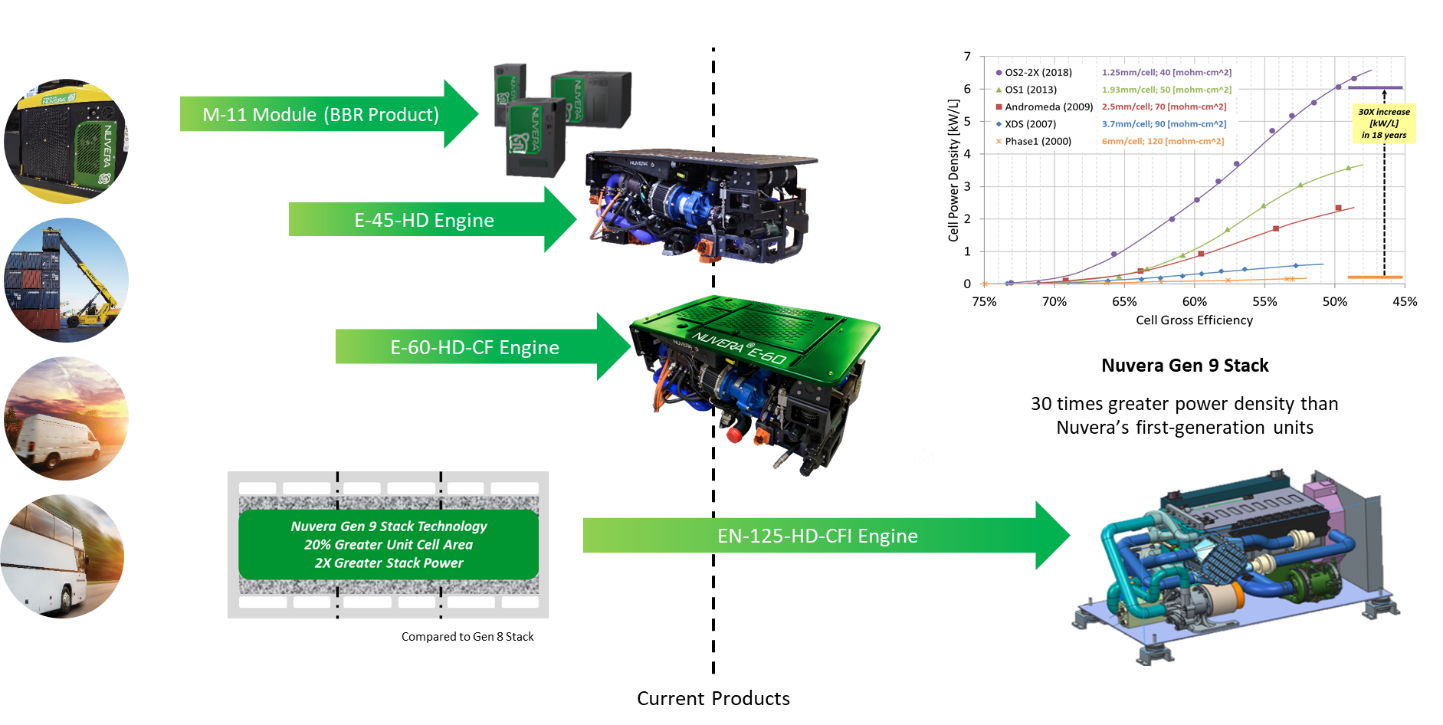

Even as our core fuel cell stack technology ― developed over the course of more than 25 years ― continues to evolve, we committed early in the development of the E-series engine product line to stay focused on meeting our customers’ fundamental requirements before moving on to what was “next.” Once the base performance of our engines was well-established and validated in real-world service, we would add features that expand our product’s capabilities as well as our range of offerings. We’ve stayed that course and are confident that we have delivered on our promise.

The Nuvera E-45 engine finished alpha testing in 2019 and was fully released to production the following year. With this first E-series engine, our focus was on having a stable base on which to build the platform. Extensive testing was done both at our Massachusetts headquarters and at our dedicated fuel cell engine test module in Osio, Italy. This includes >38,000 hours of operation under specific application duty cycles we received from our customers, as well as testing under multiple environmental conditions. The result of this work is a high-performance, high-efficiency product that we are confident can meet the demands of rigorous industrial applications while consuming as little hydrogen fuel as possible to reduce operating costs. But we’re not stopping there. We continue to refine our commercial products based on feedback we get from users in the field. We also expanded the E-Series engine product line with the introduction of the E-60 fuel cell engine in 2020, and most recently with the incorporation of full freeze-start capability. Both the E-45 and E-60 engines are available now with the ability to start from -30°C. As with the base engine development approach, we made sure this feature was well established and fully incorporated into the product before full commercial release.

The Nuvera engineering team ran hundreds of tests in many different operating scenarios to confirm the full freeze-start option would be a robust solution to the needs of our customers. Freeze-start capable Nuvera E-Series Fuel Cell Engines are now on their way to customers for incorporation into their commercial powertrains and equipment, and like our standard E-Series engines are available with short lead times for new applications. With these products fully in production, we continue to evaluate procurement sources and further improve the manufacturing process, along with other engine design updates planned. For the E-series engines we will be able to offer a full engine enclosure, and packaging that meets the space requirements of the European StaSHH program, an initiative to standardize fuel cell systems for heavy-duty applications. And even more significantly, we are in the midst of the design and release of our next-generation engine targeted at higher-power on- and off-road markets. Nuvera’s forthcoming 125 kW engine will be the first to incorporate our ninth-generation stack architecture with improved power density. This high-efficiency power system will be an easily integrated modular product that can be combined in multiples for double, triple, or even higher power.

A key aspect of our product development and quality process is obtaining customer feedback from the use of our products and soliciting input regarding what other features OEMs would like to see incorporated. In this regard we seek not only to satisfy but to delight our customers and the end-users of their products. We consider product development an evolutionary process, one that responds to new requirements that constantly emerge from the market.

If you are considering hydrogen adoption and evaluating fuel cell engine products, please don’t hesitate to reach out to our commercial team, or contact Matt personally on LinkedIn. We’d love to discuss your requirements and help you any way we can to ensure your success!